Engineers involved in data science spend around 80% of their time collecting and organizing data. At the same time, about 80% of them report that this is the part of the job they hate the most. Off-the-shelf solutions like WATS can help companies return to focusing on their core business.

The above statistic is becoming increasingly relevant for engineers and quality analysts working for Original Electronics Manufacturers and Contract Manufacturers. It tells a story that companies are spending a tremendous amount of resources on activities that adds no competitive advantage. A highly valuable source of value can be found in test data from manufacturing, and a pressing issue for many is how to best gain insight and improve from this.

A real constraint for maximizing value from test data is often that the organization is operating under a mental model leaning towards that testing is mainly an expense post at the end of the manufacturing process, without real strategic value. This mentality hinders their ability to gain insight from the data.

Rather than asking “How can all this data help our organization to improve?” the actual question becomes “What can you accomplish using existing resources, freeware or the limited IT-technology we already have invested in?” A challenge an engineer would love, getting to build something from scratch. That is not to say it is in the best interest of the company.

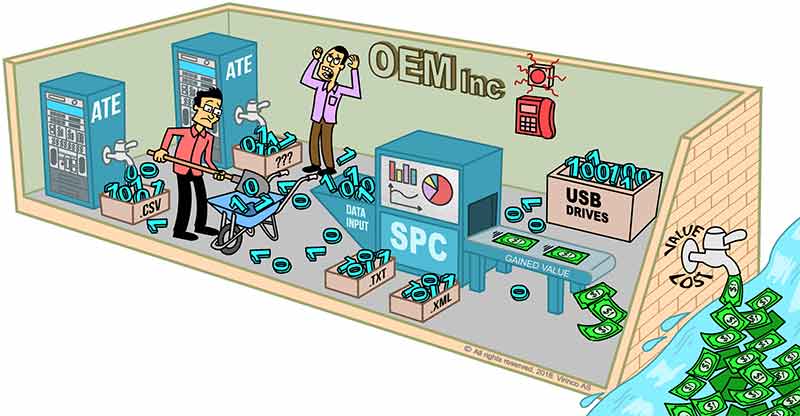

Technology that allows them to automate data-collection in real-time is rarely readily available. And at least not technology that also covers data from subcontractors. But just as the carton of milk in your refrigerator has an expiry date, so does data. Unless you are able to act on it in due time, the potential value takes a nose-dive.

Another capability rarely available is the collection of data from multiple different test formats, and uniform them so they can be cross-analyzed. So companies spend significant resources executing manual processes for this. In some cases finding that the return of investment is simply not sufficient, leaving the data unused. This is not to say that the value of the data is not there, they are simply not able to extract it at a reasonable cost.

By adopting commercially available solutions such as WATS, you free up 80% of labor for real data analytics. All else being equal this could give the average firm 5x the data insight it has today.

But all else is not equal…

WATS follows proven best-practices for analyzing the data, giving you a guide to prioritizing different improvement initiatives. The result increases in understanding, far higher than a factor of five.

In addition, you just removed the tasks that 80% of your data scientists hate the most, setting the stage for a solid morality boost.

Our trial contains existing data, or you can also upload your own. No credit card or payment details required.