Unlock the Full Power of Your Test and Repair Data

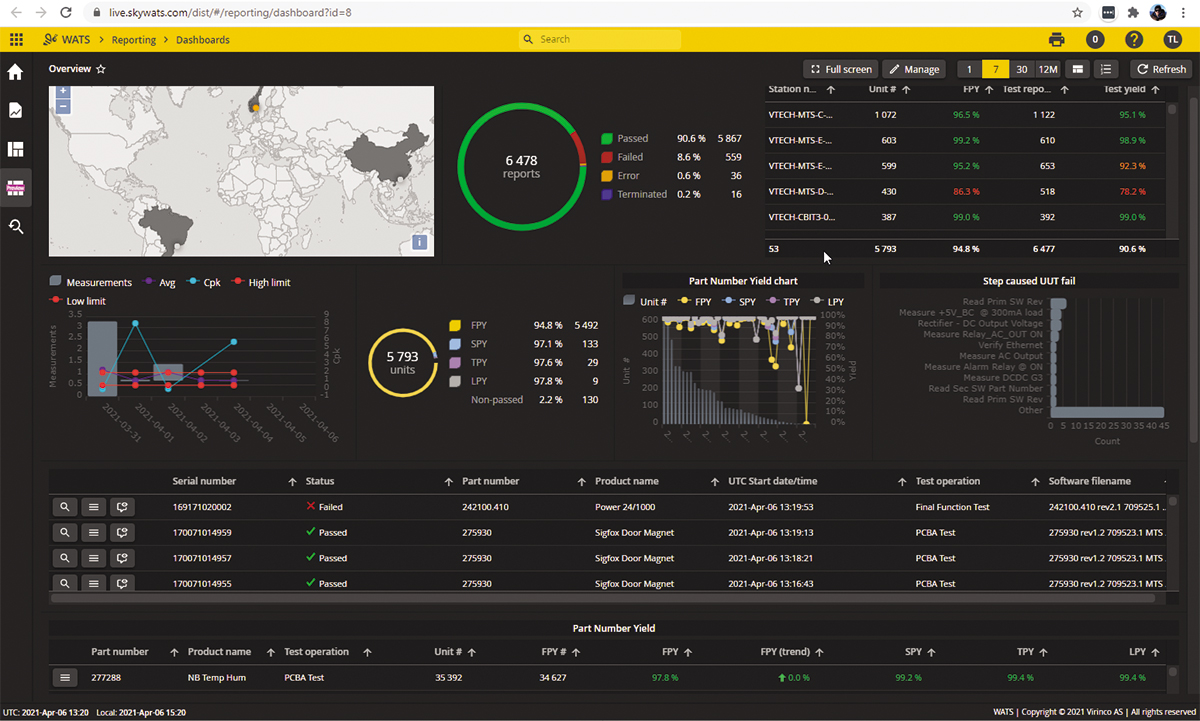

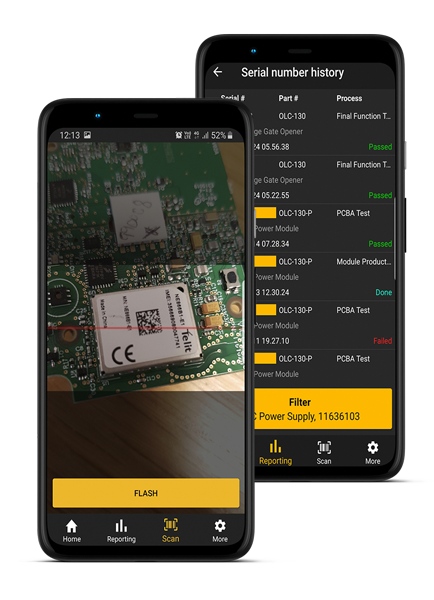

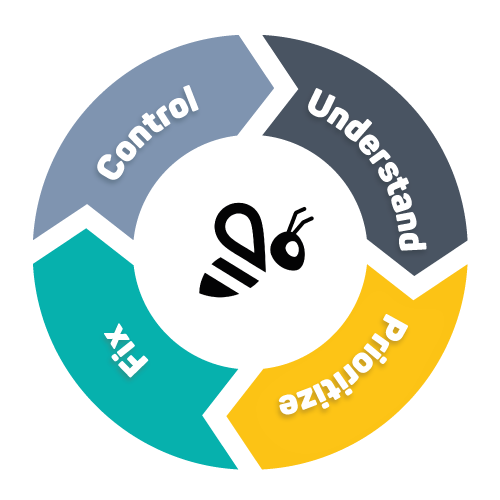

With WATS, you can collect, analyze, and act on your test and repair data. WATS unifies your data, regardless of structure, format, or source, and gives you real-time access directly in your browser.

With a comprehensive set of features you can instantly identify production yield issues, frequent product failures, poor test coverage, deviations and performance problems.