What counts as industry-leading field-failure rates in some industries can be catastrophic for a company in the Aerospace and Defence sector. There’s no room for error when you’re selling high-cost, highly complex products used in operations that can cost millions. This means that shipped products must be diligently evaluated throughout the product’s lifecycle.

Smarter Test Data Management

How do you balance this need for top-class delivery quality with the growing need to reduce costs in manufacturing? The answer lies in having visibility and a detailed understanding of your test data.

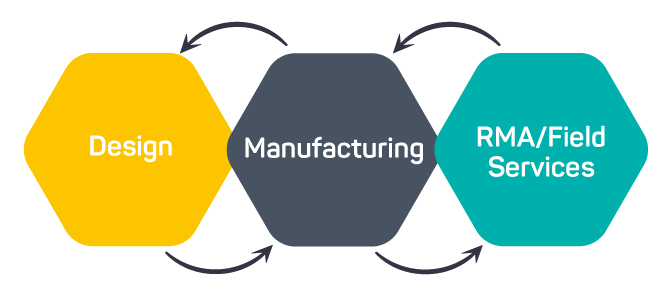

With the ability to address problems at their actual origin instead of at acceptance testing, along with a tightly integrated feedback loop between product design, manufacturing, and field performance, that is possible.

Integrate repair and field performance data

A feedback loop between design, manufacturing and field deployments allows you to continuously evaluate performance during the product lifecycle, and implement monitoring policies to proactively detect them at the time when they cost the least to fix.

With WATS Test Data Management and Repair Analytics, you can capture, aggregate and compare statistics and data from all of these stages. You can get precise control of any manufacturing process so that you reduce the risk of having a product fail at a durability test, when the actual failure should have been detected many steps earlier in the process. You can also link failures or issues found during Field Services back to the manufacturing data, to update the test coverage if needed.

”WATS has allowed us an entirely new insight into our processes. It simplifies our daily tasks and helps us to get production under control. Because yield says so much about quality, WATS reports helps spot problems almost before they begin.

Ove PedersenHead of Central Test - Kongsberg

Complete traceability, forced routing and unit verification

WATS provides you with full traceability for all units, including subunits. If a product is being repaired or returned, you can instantly access the relevant test and repair records, comparing this data with other similar products within a relevant time frame. This provides a unique learning opportunity where you get to fix actual, verified problems. See all the WATS features.

Data access and security

WATS can be deployed as a standard or private cloud service, in addition to on-premise for companies with higher security compliance requirements. It features customizable user-restriction settings, where you can configure detailed restriction settings for each user.