Are your test systems ready for the new world?

Have you thought that your test systems are responsible for checking if a product is good or not and monitoring the perhaps most crucial process in your company? The ability to manufacture electronics efficiently and accurately.

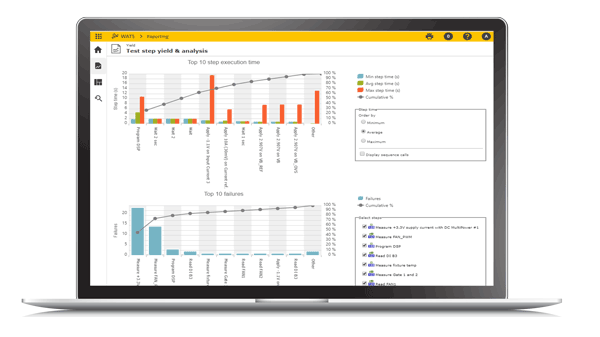

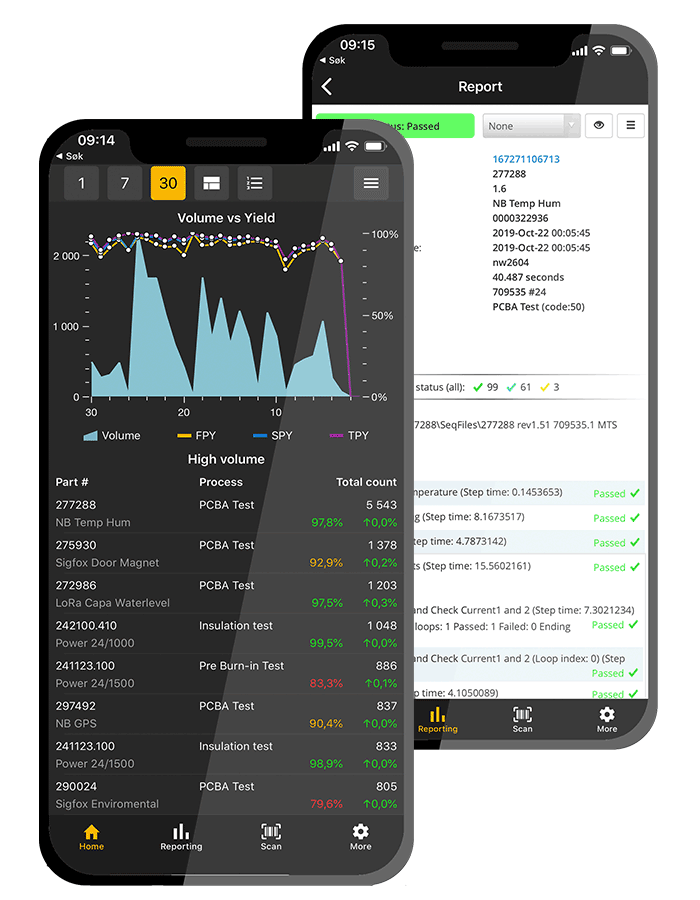

Because of this, the ability to distribute test data throughout your organization is crucial. We are not talking about moving test records but fully liberating aggregated test data and relevant performance indicators.