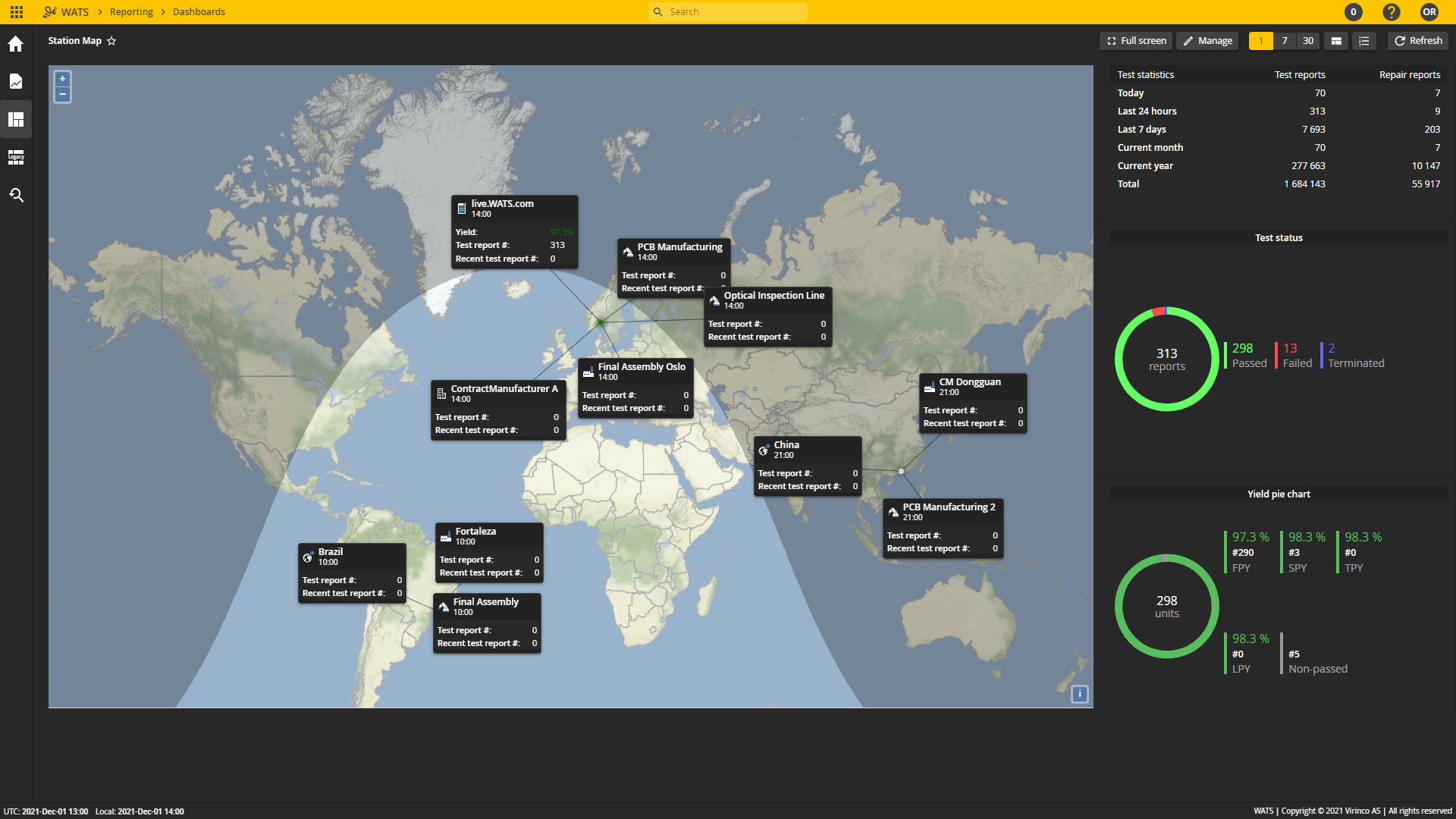

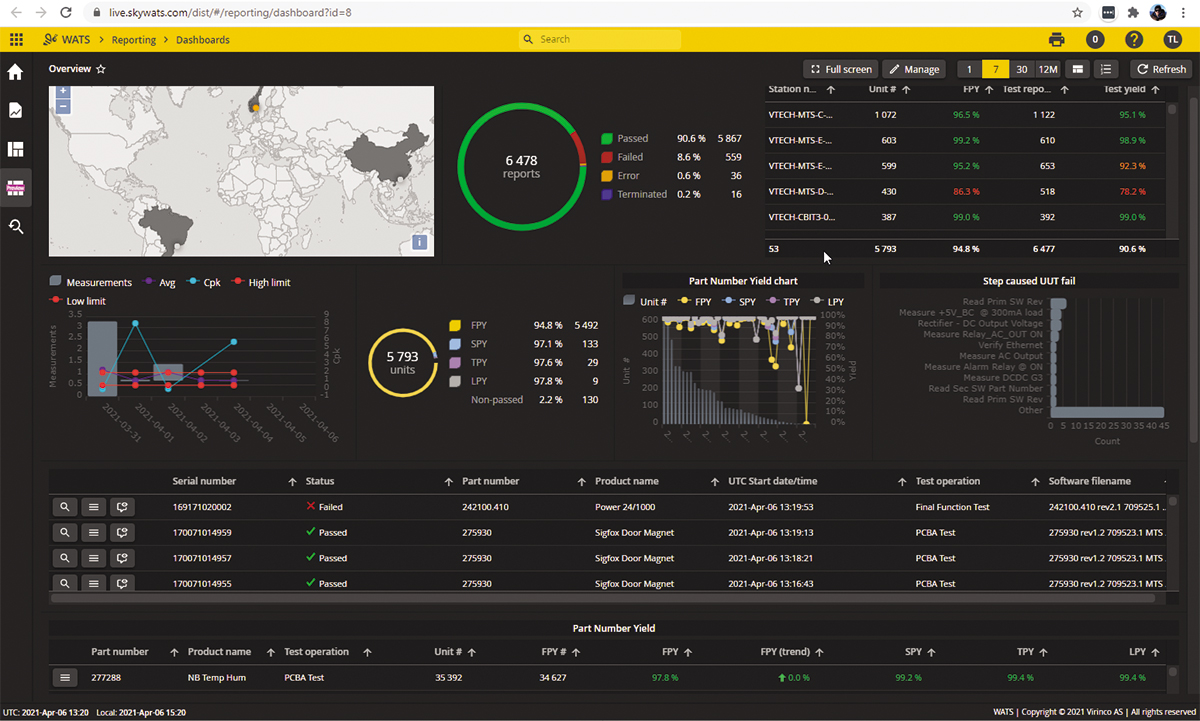

Can your team make informed decisions in real-time?

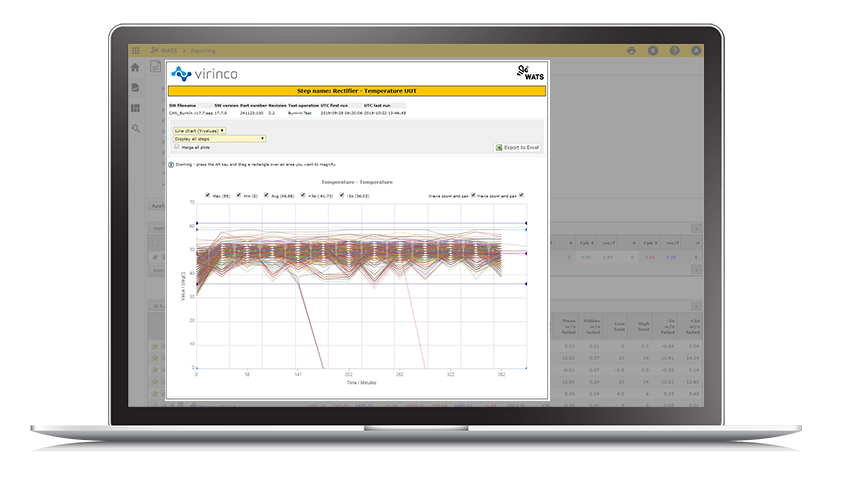

Making effective decisions based on data requires the highest standards for your data extraction and distribution architecture. It’s particularly important when your decisions impact multiple parts of your business. You need to make sure that all of your test and repair data is available to every person it impacts.