We’re well into the 21st century. Is your Manufacturing Intelligence keeping up?

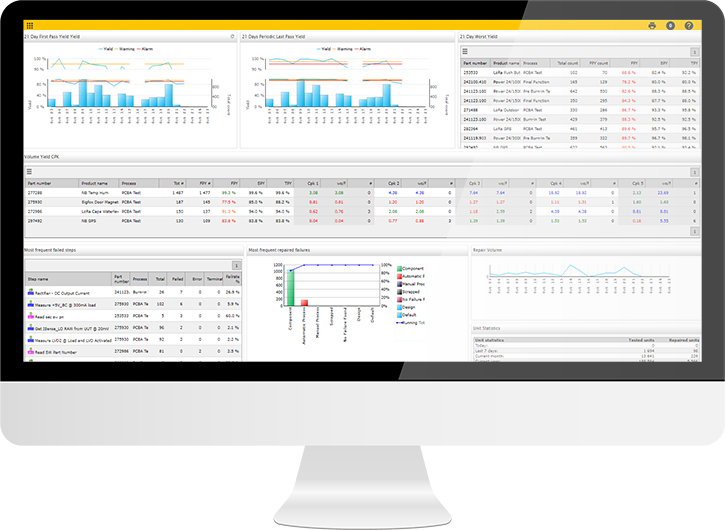

Simplified and real-time access to both contextualized and raw data from electronics manufacturing tests has the potential to significantly improve how your organization deals with New Product Introduction and evaluation of newly introduced product revisions.

Companies with good access to test KPIs spend significantly less money on wasteful activities and are able to retain more money that can be reinvested into innovation projects.