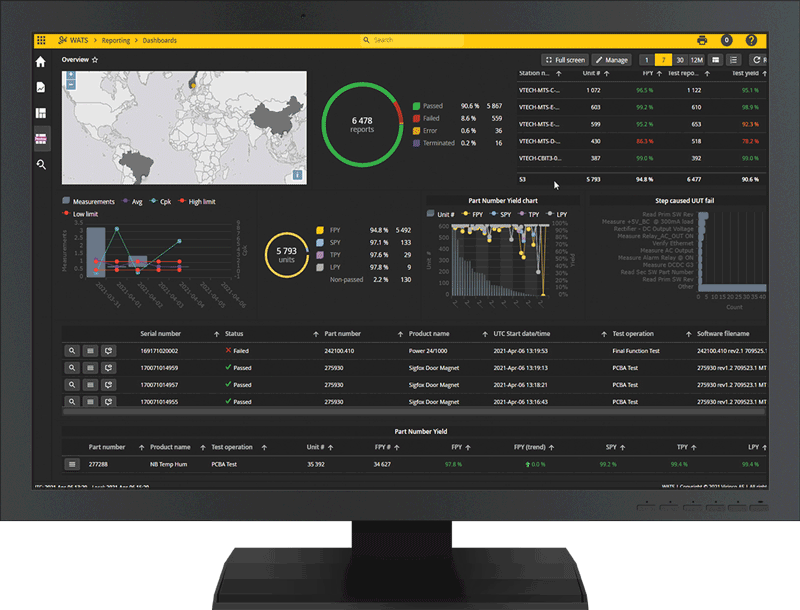

Complete visibility in manufacturing and supply chain

In modern electronics manufacturing, the processes at play are incredibly dynamic. Component changes, test system maintenance, environmental factors, different test operators, unit firmware updates, to name a few. These variables translate into a huge range of potential causes of quality issues in your products. The modern KPI toolbox for Quality Assurance must facilitate full transparency in all these areas, alongside a well-balanced ability to quickly intervene.