More Thorough Analysis Than Ever Before

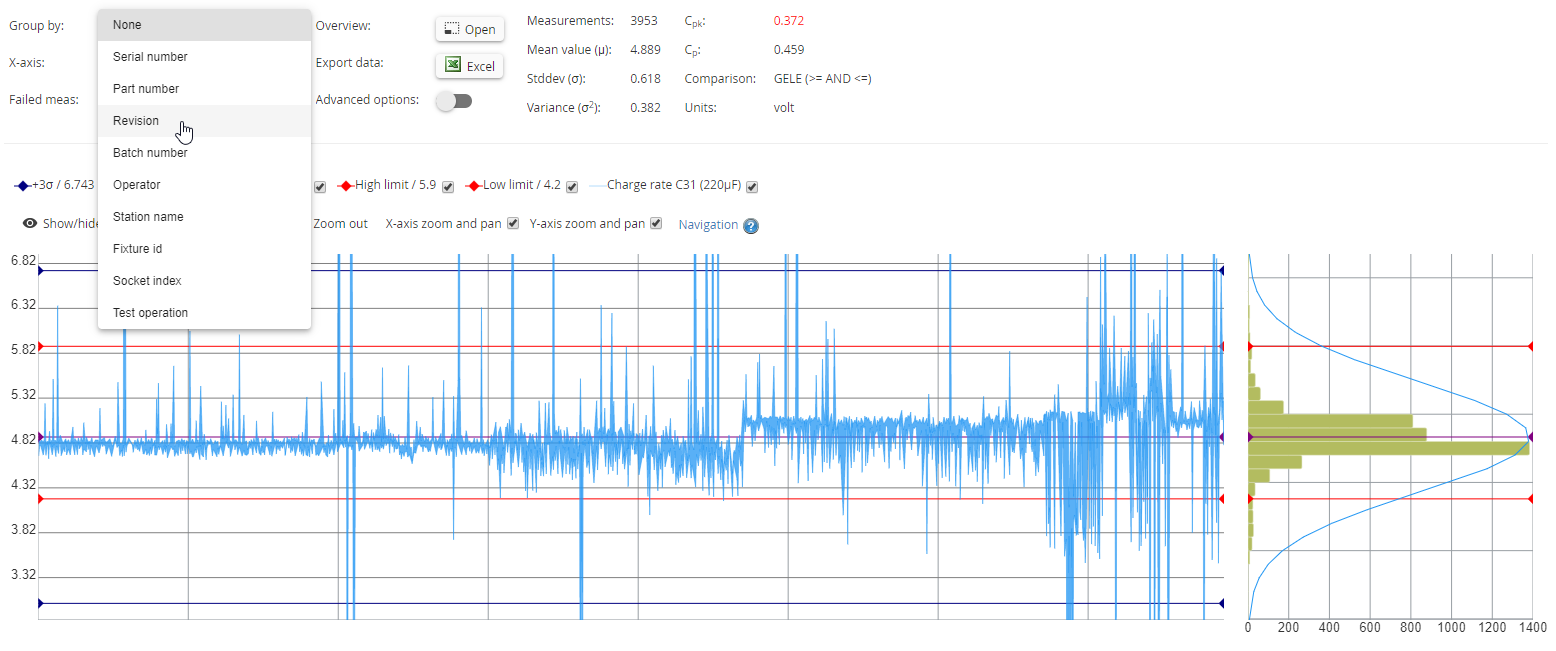

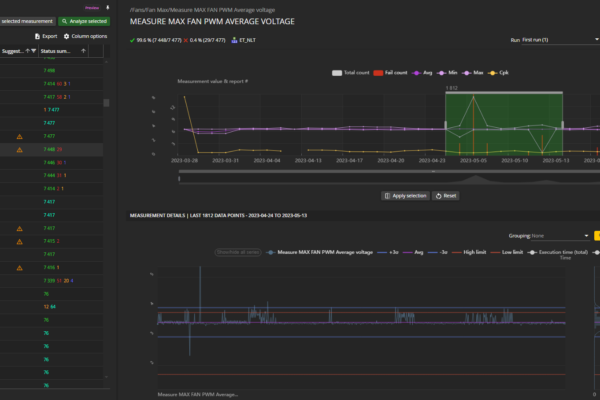

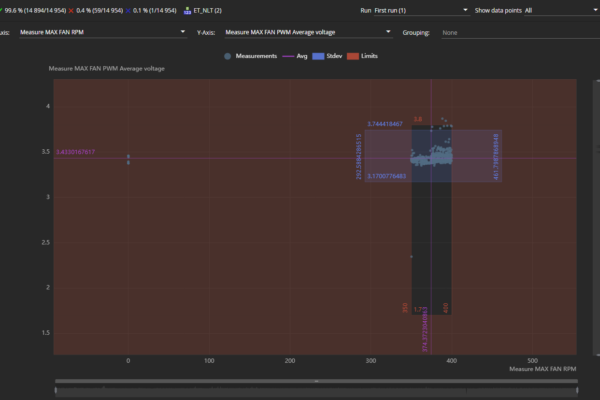

By aggregating your data WATS can straight away show you averages, mins, maxes, and CpK plotting a series against a particular index or time. And if you’re interested in zooming in on something more specific that’s available too.

For example, you might want to plot the data you have of temperature against measured voltage. This could then be displayed by test station, so you can check for outliers or make sure everything is within tolerance. It’s not just limited to test station though, you could pick test fixture, revision, operator, there’s an almost infinite number of possible combinations of measurement plotting which we’re excited to see users put to work in real testing environments.

Additional Graphing Options

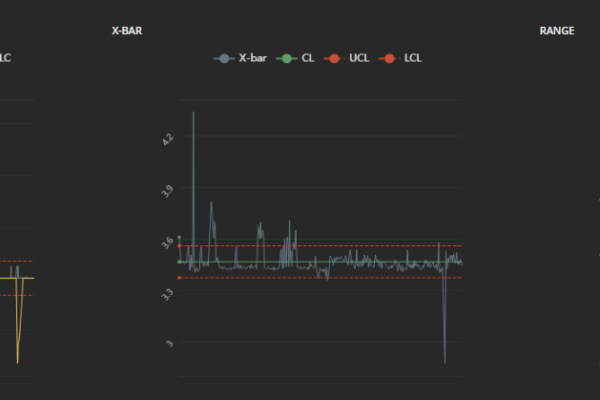

Users will also have access to additional graphing options, including I-MR, CUSUM, and X Bar. On top of that, you can use box plots to show all your data at once or go down a level and separate by test station, revision, operator – just like the other graphing options.

Two modules for Analysis

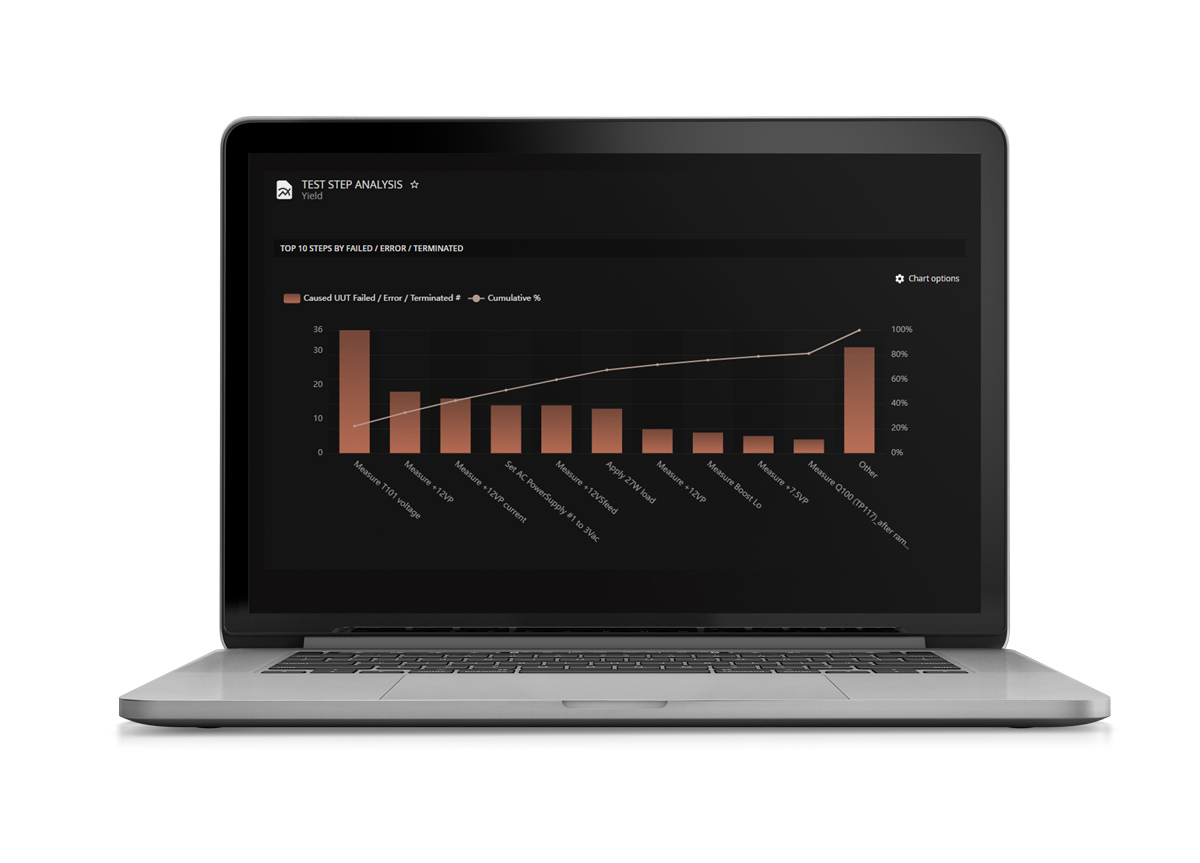

Test step analysis is a module available from the Reporting part of the Analytics application. It is used to identify which test sequences and steps to investigate, as well as providing a high level overview of different metrics and potential issues.

While considered a part of Test step analysis, Step Details is its own stand alone analysis tool. It can be opened from the Test step analysis module as well as from any step in a UUT report or from a Process Heatmap.