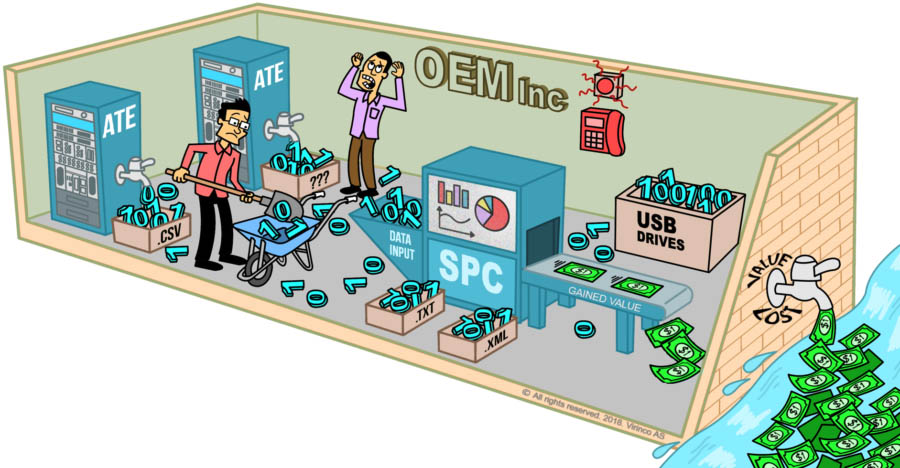

WATS Blog: Test Data Management in Electronics Manufacturing

Welcome to the WATS Blog! Explore our articles on Test Data Management in Electronics Manufacturing. You’ll find helpful insights, best practices, and advice to support your work in this field.